"Natural vs. Synthetic...Iron Oxide Color Pigments"

Custom Color Blends Available

All pigments supplied as a powder, granule, or liquid

|

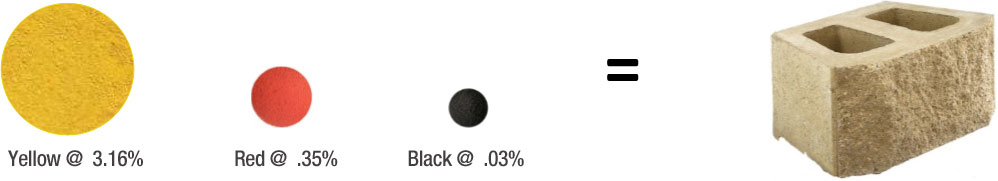

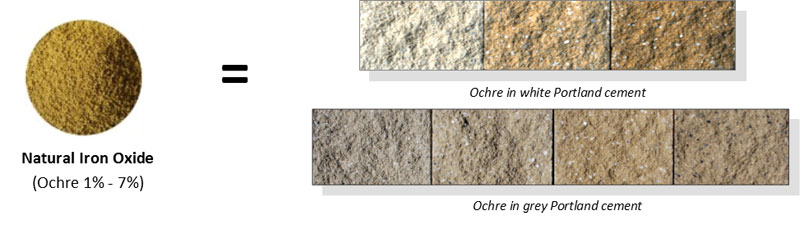

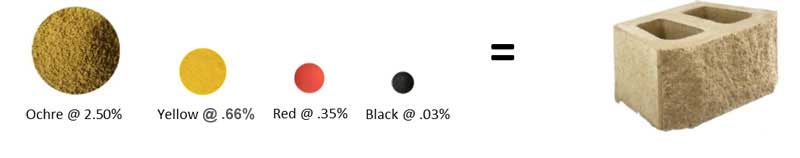

Rosetta Buff GS is a natural/synthetic blend that offers a popular buff color for the block and paver industry. |

|

Redwood GS is a reddish brown milled, calcined umber that can be used to shift synthetics into unique, natural shades. |

50 lb bags

50 lb bags

50 lb bags

50 lb bags

50 lb bags bulk

50 lb bags bulk

50 lb bags bulk

50 lb bags bulk

2500 lb super sacks

2500 lb super sacks

2500 lb super sacks

2500 lb super sacks

Bulk Loading

Bulk Loading

Bulk Loading

Bulk Loading

Packaging Options:

Ochre and Umber products are available in 50 pound bags, super sacks, and liquid totes. Custom packaging is also available.

Shipped directly from our production facility in Cartersville, GA, our pigments are packaged in 50 lb. paper bags, 2,500 lb. super sacks, liquid totes, or by bulk truck. Ochre may also be purchased from one of our distributors located across the U.S. Please call (800) 248-0176 for the location nearest you.

“How can color consistency be maintained with a natural pigment?”

Since Ochre is a mined product, many people ask the question…”How can the color be consistent when it is coming out of the ground?”

The fact is...our natural iron oxide is just as consistent as the synthetically produced pigments.

Since 1905, New Riverside has achieved color consistency by not only identifying the color of the ore during mining, but most importantly through a series of steps designed to blend the ore from multiple mine sites. By blending the ore during our processing, color shifts are minimized. Before any pigment leaves New Riverside, it is compared to a “standard” and must meet specs or it doesn’t ship!

Steps for ensuring color consistency include:

1. Selective color identification during the mining process.

1. Selective color identification during the mining process.

1. Selective color identification during the mining process.

1. Selective color identification during the mining process.

2. Ore is mined from multiple sites and...

2. Ore is mined from multiple sites and...

2. Ore is mined from multiple sites and...

2. Ore is mined from multiple sites and...

3. Mined ore is further blended in multiple...

3. Mined ore is further blended in multiple...

3. Mined ore is further blended in multiple...

3. Mined ore is further blended in multiple...

4. The production process for Ochre is monitored...

4. The production process for Ochre is monitored...

4. The production process for Ochre is monitored...

4. The production process for Ochre is monitored...

5. Every lot produced is measured against the...

5. Every lot produced is measured against the...

5. Every lot produced is measured against the...

5. Every lot produced is measured against the...

6. All production must be within specs...or it...

6. All production must be within specs...or it...

6. All production must be within specs...or it...

6. All production must be within specs...or it...

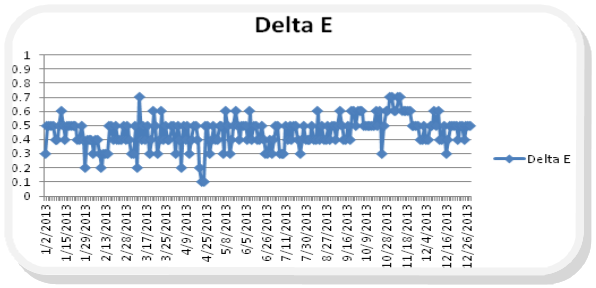

Color Consistency: The ΔE values throughout a full year demonstrate the consistency of color. Hunter L,a,b, color is monitored and held to a ΔE of 1.5

Color Consistency: The ΔE values throughout a full year demonstrate the consistency of color. Hunter L,a,b, color is monitored and held to a ΔE of 1.5

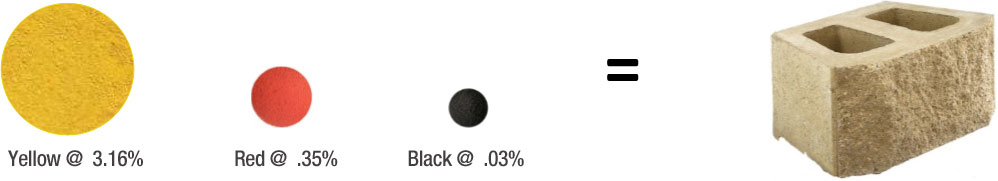

Ochre (pronounced o’-ker) is a natural, mineral, earth pigment. Chemically, it is a hydrated ferric oxide, chemical formulation: FeO(OH). Ochre is inorganic, chemically inert, non-reactive with cement, mortar or brick, and non-toxic.

New Riverside produces Ochre pigment that is called 548 Ochre. 548 Ochre is slightly dark

Ochre is mined and processed in Cartersville, GA at the only year-round Ochre mining and processing operation in the United States.

How is Ochre used? Ochre can be used alone as a single pigment to achieve a range of colors from light buff to dark buff simply by varying the addition rate. As a way to achieve a broader range of colors with a higher yellow or red shade, Ochre may also be blended with synthetic pigments and used as a cost effective base.

548 Ochre Instructions for Use

|

548 Ochre is a brown-yellow, refined natural iron oxide pigment (Fe₂O₃) with an average particle size of ~3 microns. It is the most economical buff color in the pigment industry. Broad application use for all cement applications. |

Umber is a controlled product from a manganese enriched form of goethite, a naturally occurring inorganic iron oxide. It is a brown earth pigment that is darker than the Ochre because of its manganese and iron oxide content. It is highly valued as a permanent pigment either in the raw or burnt state. Umber is lightfast, insoluble in water, resistant to alkalis and weak acids and non-reactive with cement, solvents, oils, and most resins.

How is Umber used? Raw Umber can be used to achieve a range of brown colors simply by varying the addition rate. Burnt Umber may be used as the base for producing more reddish brown shades.

|

Umber RM is a controlled brown, raw umber pigment with an average particle size of ~3 microns. It’s cost effective pricing make it suitable for a broad range of applications. It is also available as Umber RM XF, which is an extra fine powder that is ideal for the coatings industry and capable of meeting a 7 on the Hegman scale. |

|

Redwood (Burnt Umber) is a milled, calcined umber with good heat stability and suitable for all concrete applications. |

Cost Performance: Economy and versatility are the primary reasons why ochre and umber pigments have enjoyed over 110 years of success in the pigment industry.

Economical: Ochre and Umber are the most economical buff colorants available today. Ochre based blends repeatedly outperform synthetic iron oxide colors where earth tone shades are desired. On jobs ranging from a residential driveway to a 100,000-plus cubic yard drainage canal, ochre has been chosen because of its economy and performance quality.

Permanence: Because Ochre and Umber are iron oxides, their color is permanent. They will not fade or wash out. The cave paintings by prehistoric man, as well as the earth pigments used extensively in Renaissance art, attest vividly to the beauty and permanence of natural iron oxide pigments.

Ease of Use: As natural pigments, Ochre and Umber blend easily and uniformly in all applications.

Custom Colors containing Ochre and Umber as a base can be formulated to create a new “natural” range of color.

Ochre and Umber products are available in 50 pound bags, super sacks, and bulk tankers. Custom packaging is also available.

New Riverside’s success is based on “world class” mineral reserves, exceptional customer support, dedicated employees and a technical staff commited to producing high quality products and value for their customers.